Introduction

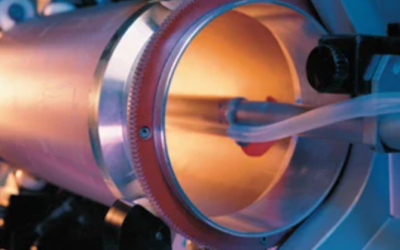

In the ever-evolving landscape of innovation, the most intriguing connections often arise from unexpected unions. Today, we explore an unlikely yet fascinating pairing that transcends industry norms—the convergence of SPGPrints’ Rotamesh rotary printing screens and Elon Musk’s SpaceX reusable rockets. While seemingly worlds apart, with one transforming the printing industry and the other pushing the frontiers of space exploration, these innovations share a remarkable commonality.

SPGPrints Rotamesh: Pioneering Sustainable Rotary Screen Printing in the Flexographic Label Market

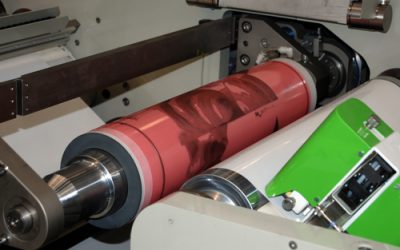

In the modern printing industry, sustainability and cost-effectiveness are not just trends but imperatives. As flexographic label printers seek more environmentally friendly and economically viable solutions, SPGPrints’ Rotamesh stands out as a beacon of innovation and sustainability.

This solution becomes particularly impressive when compared to alternatives like Kocher & Beck Tecscreen and Gallus Screeny rotary screens, which, while they can be effective in certain conditions, they lack the crucial element of reusability.

In this context, the reusability of SPGPrints Rotamesh not only mirrors Elon Musk’s vision for SpaceX reusable rockets but also emerges as a game-changer in terms of environmental impact and long-term cost efficiency.

Elon Musk’s Vision: A Relevant Comparison

Elon Musk’s groundbreaking work with SpaceX reusable rockets offers a pertinent parallel. Initially, the concept of a reusable rocket seemed a costly venture. However, over time, the repeated use of these rockets has brought down the cost of space exploration significantly. Similarly, Rotamesh, with its innovative reusability feature, represents a long-term investment that promises decreased costs as production volume increases.

The Reusability Advantage of SPGPrints Rotamesh

A Paradigm Shift in Rotary Screen Printing

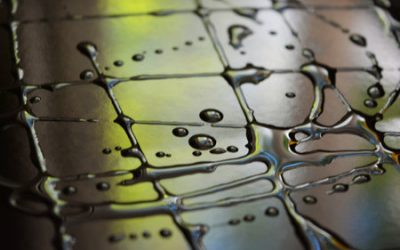

Rotamesh’s ability to be stripped of its emulsion, recoated, and re-imaged for new print jobs is nothing short of revolutionary in the flexographic label printing market. This feature, unavailable with products like Kocher & Beck Tecscreen and Gallus Screeny, offers significant advantages:

- Cost Efficiency Over Time: Like SpaceX’s reusable rockets, the initial investment in Rotamesh may be higher, but the overall costs decrease significantly over time, especially when production is scaled up. Reusability means fewer screens need to be purchased over the long term, reducing the cost per print.

- Reduced Environmental Impact: The reusability of Rotamesh is a major step towards sustainability in the printing industry. By minimising waste and reducing the need for new materials, Rotamesh aligns with the growing emphasis on environmental responsibility.

Sustainability: The Core of SPGPrints Rotamesh

The Environmental Imperative

As the printing industry becomes more conscious of its environmental footprint, solutions like Rotamesh are gaining prominence. By allowing screens to be reused, Rotamesh drastically cuts down on waste. This is in stark contrast to products like Tecscreen and Screeny, which, once used for a particular job, cannot be repurposed for another, leading to a cycle of constant consumption and disposal. Indeed these solutions are very costly in terms of high waste.

In addition, the undoubtedly higher quality mesh used in Rotamesh technology means greater stability and far less downtime due to damage to the rotary screen. Attributes that the competition cannot match. In fact, users of these other rotary screen products should be used to using more than one screen to cover breakages just to print a single job. This simply does not happen with Rotamesh.

Aligning with Industry’s Green Goals

Rotamesh aligns seamlessly with the industry’s push towards sustainability. Its reusability means that the production process uses fewer resources over time, which is vital in an era where sustainable practices are not just preferred but often mandated by industry standards and consumer expectations.

Economic Benefits: Analysing Long-Term Savings

The Economics of Reusability

In the same way that SpaceX has revolutionised space travel economics, Rotamesh is transforming the cost structure of the flexographic label printing industry. The ability to reuse the same screen for multiple jobs means that the amortised cost of each screen decreases with every use. This translates to substantial savings for printers, especially those with high-volume operations.

Scalability and Efficiency

For businesses looking to scale up their operations, the reusability of Rotamesh provides a clear path to increased efficiency and cost reduction. As production volumes grow, the need for new screens diminishes proportionally, allowing printers to optimize their operations both economically and operationally.

A Comparative Analysis with Competitors

Kocher & Beck Tecscreen and Gallus Screeny: One-Time Use Limitations

Both Kocher & Beck Tecscreen and Gallus Screeny are known for their quick turnaround and low cost in rotary screen printing. However, their lack of reusability presents a significant limitation. Once a specific job is completed, these screens cannot be repurposed, necessitating the purchase of new screens for subsequent jobs. This ongoing requirement not only increases material costs but also contributes to environmental waste.

Rotamesh: The Superior Alternative

In contrast, SPGPrints Rotamesh emerges as the more sustainable and cost-effective alternative. Its ability to be reused multiple times makes it a more financially viable option in the long term and a more environmentally friendly solution.

CONTACT US TODAY or call +44 (0)1255 240444