Rotary screen printing is a vital technology in the world of label and graphics production, offering unparalleled efficiency and quality. At the forefront of this technology is SPGPrints, a Dutch company renowned for its innovative printing solutions, particularly the Rotamesh screen print cylinder and the RSI print unit. These tools are designed specifically for the high demands of the label and graphics print industries.

In the UK, MPH Limited is responsible for translating these technological advancements into practical, everyday printing solutions. As the official pre-press partner of SPGPrints, MPH Limited produces and prepares Rotamesh screens that are ready for immediate use, catering to demanding markets such as printed electronics and the graphic print industry.

Learn how these high-quality Rotamesh screens, which have been standardised to meet the rigorous requirements of the electronics market, bring substantial value to flexographic label printers across the UK.

The Core of Rotary Screen Printing: SPGPrints’ Technologies

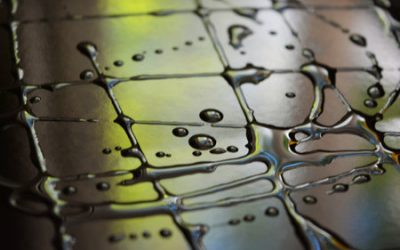

SPGPrints has set a benchmark in the printing industry with its Rotamesh screen print cylinders and RSI print units. The Rotamesh screen, a non-woven nickel mesh, is engineered for strength and durability. The technology is particularly designed to handle the rigorous demands of fast-paced printing environments, making it an ideal choice for both the label and graphics print industries. This technology allows for a finer mesh that provides unprecedented ink control and deposition, which results in sharper images and richer colours on the final print.

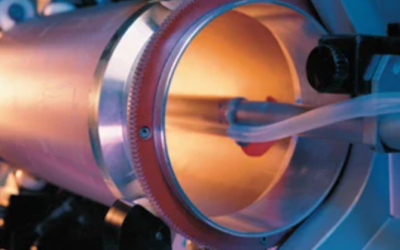

The RSI (Rotary Screen Integration) print unit seamlessly integrates with existing label printing setups, enhancing them with the capability to perform complex, multi-colour jobs in a single pass. This integration not only optimises production times but also improves the overall quality of the print, making it a crucial tool for printers who prioritise both efficiency and quality.

MPH Limited: Pioneering Pre-Press Excellence in the UK

As SPGPrints’ designated pre-press partner in the UK, MPH Limited plays a critical role in the supply chain of high-quality printing products. Strategically located to serve the UK market, MPH Limited specialises in producing and preparing Rotamesh screens that are customised to meet the specific needs of their clients.

MPH’s state-of-the-art pre-press facilities ensure that each screen is meticulously crafted to achieve the highest standards of precision and quality.

MPH Limited’s expertise extends beyond screen preparation to encompass the stringent quality demands of the printed electronics market. This market requires extremely high precision due to the functional nature of the products being printed, such as circuits for electronic devices, including medial home test kits.

By adopting these high standards across all their products, MPH Limited ensures that even the graphic print market benefits from the enhanced quality originally intended for electronic applications.

Bridging Markets: High Standards for Electronics and Graphics Printing

The elevated standards required by the printed electronics market serve as a benchmark for all screen production at MPH Limited. This cross-market standardisation ensures that the flexographic labels produced using these screens are of exceptionally high quality, which is critical in a market where even minor imperfections can lead to significant losses.

For instance, the precision required in electronic printing, where a slight misalignment could render an electronic device useless, translates into an unmatched quality control in label printing when using MPH made rotary screens. Further, the rigorous demands of the medical and pharmaceutical market places MPH operates in requires exceptionally high standard of consistency and print repeatability.

This commitment to excellence ensures that flexographic printers who utilise MPH Limited’s Rotamesh screens can benefit from reduced downtime and fewer press issues.

The partnership between SPGPrints and MPH Limited offers numerous advantages to flexographic printers in the UK. The use of Rotamesh screens ensures that printers can achieve a higher level of detail and colour consistency, which are crucial for brands that rely on distinctive packaging as part of their product appeal. Additionally, the durability of these screens reduces the need for frequent replacements, thereby lowering operational costs and increasing print run efficiencies.

Moreover, by leveraging the high standards set for the electronics market, UK printers can differentiate themselves by offering superior print quality that can handle even the most demanding designs and applications. This capability is particularly beneficial for printers looking to expand their services into high-end markets, including luxury goods and specialised retail.

The collaboration between SPGPrints and MPH Limited is revolutionising the rotary screen printing landscape in the UK. By adopting Rotamesh screen printing technology, UK-based flexographic printers gain access to a product that meets the high-quality standards of the electronics printing market, thus adding a valuable dimension to their printing capabilities. For printers aiming to enhance their output quality and operational efficiency, it is not just an option to consider the advanced solutions offered by MPH Limited and SPGPrints; it is a strategic necessity.

This integration of high standards across different printing applications not only maximises printer potential but also aligns with the evolving needs of the dynamic printing industry.

For further information and to discover how these pioneering printing solutions can enhance your production capabilities, please contact MPH today.

CONTACT US TODAY or call +44 (0)1255 240444